Drill holes in an open pit were being backfilled using a stemming bucket attached to an integrated tool carrier (IT). During the process, a worker from the drill and blast crew noticed that the backfill material had stopped flowing from the stemming bucket into a drill hole.

After using hand signals to communicate with the IT operator, the worker attempted to dislodge the blockage by placing his hand in the discharge outlet at the base of the stemming bucket. The hydraulically actuated gate valve, which controls the flow of material through the discharge outlet, closed and severed several of his fingers.

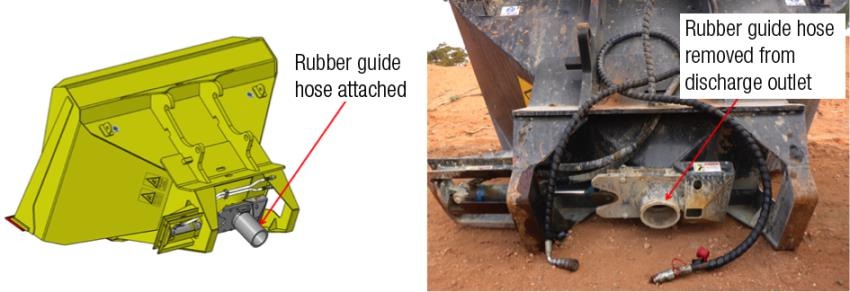

A subsequent investigation revealed that the rubber guide hose provided by the original equipment manufacturer (OEM) to fit over the discharge outlet, and guide the flow of material into drill holes had been removed. This allowed the worker to access the discharge outlet.

Direct causes

- The worker's hand was exposed to moving parts.

Contributory causes

- The plant was not isolated while attempting to dislodge the blockage.

- Despite regular blockages, there was:

- no mechanism to prevent oversize material from blocking the discharge outlet

- no risk assessment for clearing blockages

- no safe work procedure (SWP) or safe work instruction (SWI) for clearing blockages.

- A rubber guide tube attached to the discharge outlet of the stemming bucket had been removed, modifying the OEM’s design. No risk assessment was conducted after the stemming bucket was altered.