Summary of incident

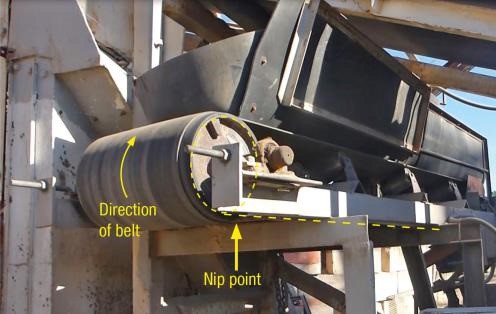

In June 2016, a boilermaker, working alone, was in the process of shutting down a crushing plant. A conveyor, positioned at head height, was part of the crushing circuit and adjacent to a screen deck.

The boilermaker observed a rock rotating in the nip point of the conveyor’s tail-end pulley. Material from the screen deck had accumulated on the ground beside the conveyor next to the nip point. He stood on this material and reached between the belts with both hands, using a spanner in an attempt to knock out the rock. However, the moving conveyor had not been isolated.

Both his arms were drawn into the conveyor’s nip point. Fortunately, he managed to free his arms when the tail-end pulley came to a stop and was able to seek emergency assistance. The boilermaker was hospitalised with a de-gloving injury, friction burns and multiple fractures to his hand, arms and back.

Direct causes

- The conveyor was not guarded to prevent access to moving parts.

- The conveyor was not isolated before the attempt was made to remove the rock.

Contributory causes

- Materials from the nearby screen deck were not effectively controlled, resulting in a rock landing inside the belt.

- The build-up of material on the ground enabled easy access to the nip point of the conveyor.

- No isolation procedure had been developed for the conveyor.