Workers have been exposed to potentially serious injuries when using hydraulic tools to extract pins from articulated joints on heavy earthmoving machinery. Recent examples include:

In September 2018, a 13 kg pulling rod failed and was projected approximately 26 metres during pin cartridge removal from the boom of a front end loader.

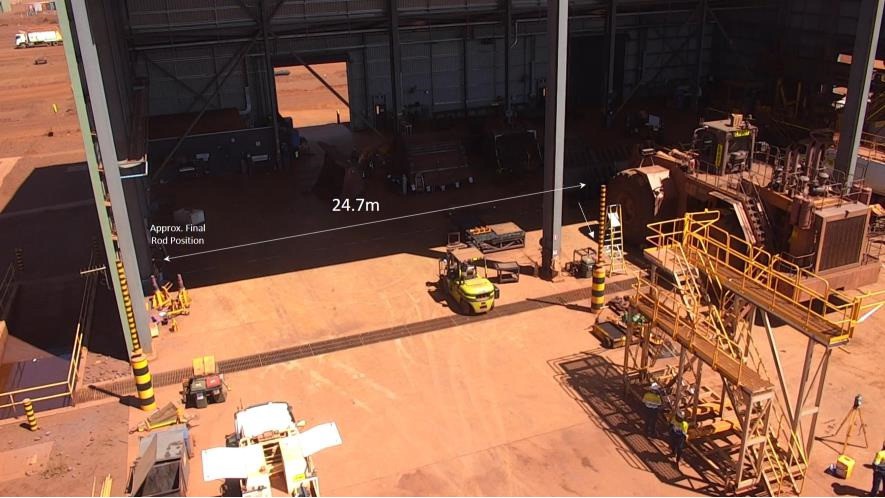

In January 2019, a 19 kg pulling rod was projected approximately 25 metres and embedded itself into the workshop wall, during removal of bucket pin on a front end loader.

Direct causes

Failure of incorrectly selected pulling rod under tension generated by hydraulic cylinder actuator.

Contributory causes

- Pulling rods were incorrectly matched with the higher capacity hydraulic cylinders.

- Purpose designed and built original equipment manufacturer (OEM) tooling was not used.

- Selected engineering control (special purpose tooling) was ineffective at managing identified hazards.

- Workers were not trained and assessed as competent in the task they were carrying out.

- Safe system of work relating to the task and contractor management was not adequate.