Background

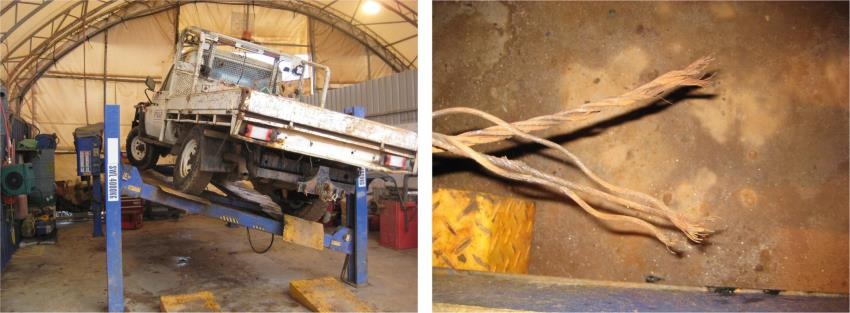

The department has received numerous reports of failed and damaged equaliser cables on vehicle hoists, including those types with two or four posts.

The equaliser cables are typically made using steel wire rope and are used to keep the hoist level during raising and lowering. Over time, equaliser cables can stretch, fray, corrode, crack or break and therefore should be regarded as a wearing component.

Inspection and testing on equaliser cables should be carried out by competent persons, such as the appointed classified plant inspector.

An understanding of the specific vehicle hoist requirements is imperative, especially when inspecting these in situ as cables pass around sheaves and behind guards and guides, limiting visibility.

Vehicle hoists are registrable classified plant and are subject to periodic statutory inspections.

Summary of hazard

Failure of the equaliser cable on a vehicle hoist has a high potential for serious or fatal injuries as a result of:

- a worker being crushed

- a worker being impacted by an uncontrolled release of energy.

Contributory factors

- Inspection of equaliser cables being carried out by workers who are not:

- competent to inspect cables

- familiar with the original equipment manufacturer's (OEM's) procedures to ensure the entire cable is inspected.

- Equaliser cables being subjected to corrosive environments, solvents and/or frequent washing. The cable material can be incompatible with these conditions, particularly if inadequately lubricated.

- Secondary hoist safety catch systems failing to fully engage under sudden cable failure.