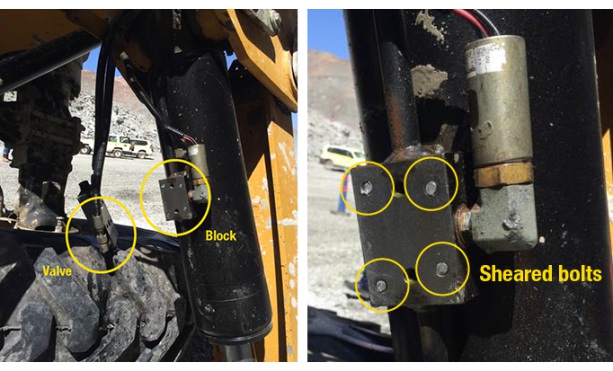

A worker in a pit was conducting ground support activities from a work basket attached to a telehandler elevated about 12 metres above the ground. The worker was manually removing a rock from the face when it fell, striking the hydraulic check valve block on the right-hand front jack of the telehandler.

The impact dislodged the check valve block, releasing hydraulic fluid. The affected jack retracted, destabilising the tele-handler, which then tipped on to its side. The work basket became wedged against the wall, 6 metres above the pit floor, trapping the worker's legs. The mine’s rescue team extricated the worker, who had a fractured lower right leg and crush injuries to his left foot.

Direct causes

- A rock struck and damaged the check valve block causing hydraulic fluid release and retraction of the jack.

Contributory causes

- The original equipment manufacturer’s (OEM’s) check valve covers were inadequate to prevent damage from impact by large or heavy objects.

- Work planning did not consider the potential for equipment to be struck by falling rocks outside the demarcation zone.

- The design of the work basket did not prevent the extension of body parts past the basket's edge protection during uncontrolled movement.