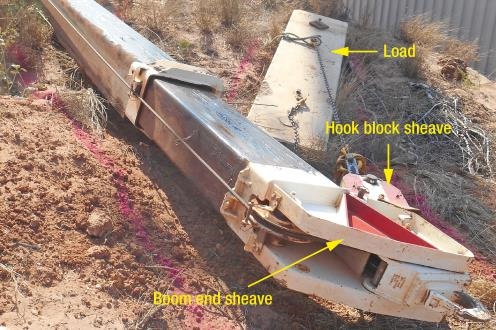

In November 2015, an articulated, pick-and-carry mobile crane at a mine site was positioning a cyclone tie-down block weighing about two tonne. The crane operator moved the machine with the boom almost fully extended, the hook block sheave in hard contact with the boom end sheave (known as two-blocking), and a swinging load (with no control on the tag line).

As the crane moved backward, was articulated, then moved forward, a front wheel travelled onto soft material on sloping ground and the crane tipped onto its side. The dogman, who was acting as a spotter, had to move quickly to avoid injury as the crane rolled towards him. The crane operator was uninjured.

Direct causes

- The crane was being operated outside of its design criteria, changing its centre of gravity and destabilising the machine:

- the boom was almost fully extended and elevated

- the crane was articulated while travelling, with the load raised and swinging.

- The ground was sloping and uneven (e.g. front wheel travelled from sealed hardstand to uncompacted material).

Contributory causes

- The hazards associated with moving the load were not fully identified or controlled. For example, the boom end sheave and hook block sheave were in hard contact (i.e. two-blocked).

- The mine site verification of competency appears to have been remiss in identifying shortfalls in the competency of the crane operator and dogman.