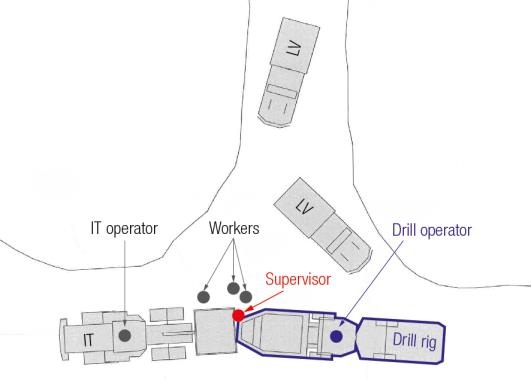

In December 2015, an integrated tool carrier (IT) was parked in an underground main level access, while three workers and a supervisor inspected a damaged man-basket. Two light vehicles (LVs) were parked in an adjacent stockpile. All the parked vehicles had illuminated, flashing beacons.

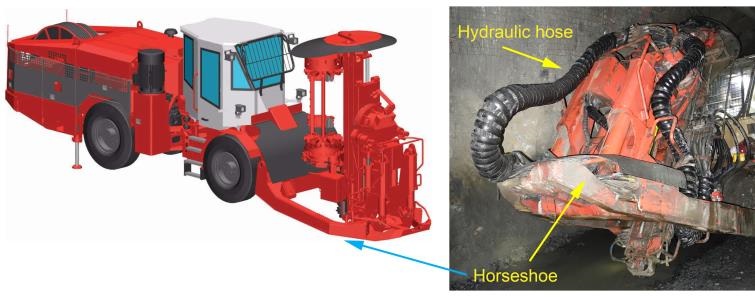

At the same time, a long-hole drill rig was slowly tramming (horseshoe first) out of the level to the next drill location. While the drill operator was looking for an area to turn the rig around (to tram engine-first), the horseshoe made contact with the IT’s basket.

The supervisor – who was facing the basket, taking photographs at the front of the IT – was pinned between the basket and the long-hole drill rig’s horseshoe and hydraulic hoses.

Colleagues provided first aid to the injured supervisor until the site ambulance arrived and brought him to the surface. He was transferred to the local hospital for assessment where he underwent surgery for crush injuries to his lower abdomen. Fortunately, his injuries were limited to severe bruising, which required internal stitches.

It appears there was no attempt to communicate with the drill rig operator before his vehicle made contact with the IT.

Direct causes

- The IT was stopped in a high traffic area of the main level access.

- The workers and supervisor were standing next to the IT.

Contributory causes

- Lack of effective communication between personnel.

- Failure to recognise and manage the risks associated with working around mobile equipment.

- The drill operator’s field of view was reduced by tramming the long-hole drill rig horseshoe first.

- The stockpile was obstructed by the parked LVs, preventing the long-hole drill rig from turning around.

- Failure to manage the risks associated with congestion and mobile plant egressing underground levels.