Summary of incident

In January 2017, an operator was in the process of setting up a block-making machine to manufacture limestone blocks. The machine was switched on and set to operate in auto mode.

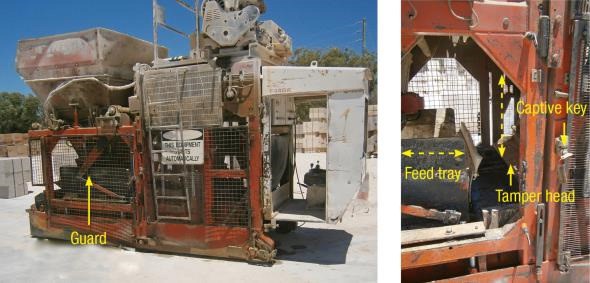

The operator noticed a large rock in the machine’s feed tray and opened a safety guard on the side of the machine, entering an area between the tamper head and feed tray. While attempting to remove the rock, the machine began operating, trapping him between the moving tamper head and feed tray.

Note: In auto mode, a signal from the level sensor (located at the feed tray area of the machine) will start the block-making process.

Another worker walking towards the machine noticed the guard in the open position and the injured operator. The worker switched the machine from auto mode to manual mode (disabling the sensors) and raised the tamper head to free the operator. After receiving emergency medical treatment, the operator was transferred by helicopter to hospital with very serious, multiple injuries.

The original equipment manufacturer included an interlock unit and captive key system for isolation purposes. A key is required to start the machine's hydraulic system using the start switch located in the operator’s cabin. The same key should be used to open any of the machine’s guards. However, the key must be turned to the off position (shutting down the hydraulics) before it can be removed. In the same way, the guard must be in the closed position before the key can be removed and used to restart the machine.

The scene examination identified that two captive keys were actually in place on the machine at the time of the incident. One of these was located in the safety guard locking arrangement (interlock unit), which was used to open the guard, while the other was in the start switch, which left the machine operating in auto mode.

Direct causes

- The operator entered the guarded area of the block-making machine while the machine was not isolated and set to operate in auto mode.

Contributory causes

- The block-making machine had been set up prior to the incident to operate in auto mode.

- The machine's main electrical isolation switch was not functional.

- Both captive keys were in interlock units at the time of the incident, allowing access to the guarded area while the machine remained under power in auto mode.