Summary of incident

In October 2016, specialist contractors were attempting to remove a trunnion pin from a reclaimer’s luffing cylinder using a purpose-built, hydraulically powered extraction implement.

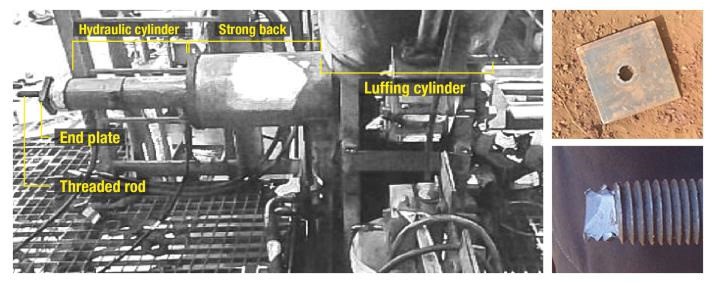

Note: The extraction implement consisted of a hydraulic cylinder that pulled on an end plate, which in turn pulled on the reclaimer’s trunnion pin via a threaded rod.

Removing the trunnion pin was difficult and there were several attempts to extract the pin. On each attempt the pulling action of the extraction implement was increased.

Note: The maximum pressure applied was reported to be 90 per cent of the hydraulic system's capacity.

After the fifth attempt the threaded rod failed unexpectedly, releasing stored energy. The rod and end plate were ejected from the work area (on an elevated maintenance platform of the reclaimer). The end plate missed an operating crane and was found about 20 metres away on the ground.

Further investigation identified that the threaded rod had failed due to tensile overstress.

Direct causes

- The load applied by the hydraulic system exceeded the tensile capacity of the threaded rod.

Contributory causes

- No safe operating limits were specified in the safe work procedure or job hazard assessment.

- There was inadequate safety-in-design consideration for the implement as the hydraulic system was capable of exceeding the breaking capacity of the threaded rod.

- Engineered protection devices (e.g. pressure relief device) were not designed or installed correctly to protect the system from inadvertent overloading.

- The controls for the safe use of the implement were not identified as inadequate in the risk assessment process.

Note: The specialist contractor had previously carried out similar tasks using similar equipment for the mining operation. - The threaded rod was not adequately rated or assessed by a competent person.

Note: No detail drawings could be provided at the time of the investigation. Also, the site’s supervisory team assessment of the capacity of the threaded rod was incorrect.