Summary of incident

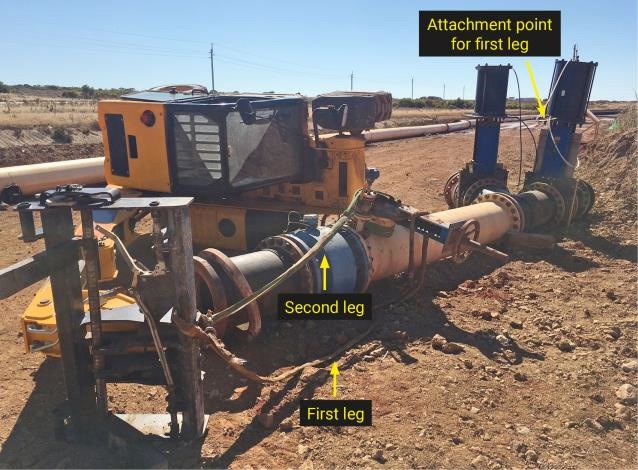

In January 2017, a telehandler was being used to lift a pipe assembly at a tailings storage facility. A worker had attached the first leg – a single roundsling rated to three tonnes – to a knife gate valve while the other end was choked around the tool carrier frame. A second leg – comprising two connected two tonne-rated roundslings – was attached to a branch of the pipe assembly. This was then secured to a shackle placed through a hole in the tool carrier frame.

As the load was lifted, the three tonne-rated roundsling broke and the telehandler fell on its side. The worker was standing near the telehandler when it hit the ground.

Direct causes

- The three tonne-rated roundsling failed

Note: The sling had been damaged prior to the incident when it was used to drag a section of pipe over hard and rocky ground.

Contributory causes

- The three tonne-rated roundsling initially took more of the load when the pipe assembly was lifted.

- The weight of the pipe assembly (over 3 tonnes) was greater than the maximum-rated lifting capacity of the telehandler (2.5 tonnes).

- The work required the use of slinging techniques for the purposes of lifting a load, for which a dogging high risk work licence is the minimum requirement. The worker that slung the load did not have an applicable high risk work licence.

- The telehandler operator had a high risk work licence and had been assessed as competent for using the tynes on the telehandler, but had not been assessed as competent for lifting freely suspended loads.

- The roundsling that failed was attached to an unrated lifting point on the knife gate valve and was choked around the tool carrier frame which had sharp edges.