Summary of incident

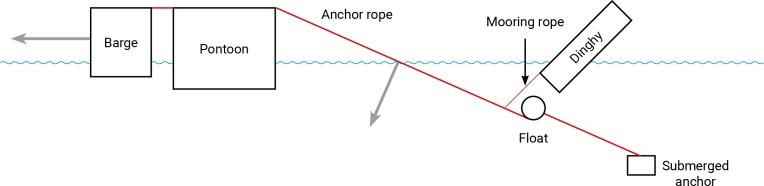

In May 2017, two workers were tying-off the anchor rope of a pontoon to the float of a submerged anchor in a dredge pond to hold the pontoon in position. One worker was in a dinghy tying-off the anchor rope, the other worker was holding the pontoon in position using a barge.

During the tying-off process the dinghy’s mooring line became entangled with the pontoon’s anchor rope. As the barge pulled on the pontoon to take up slack in the anchor rope, it caused the float and anchor rope to pull down on the entangled mooring line, capsizing the dinghy.

When the worker in the dinghy fell into the 3.5 metre deep water his personal flotation device (PFD) failed to inflate automatically. Fortunately, he was uninjured and able to climb onto the hull of the overturned dinghy. Though he was unable to raise the alarm due to his radio having been submerged, his co-worker saw the capsized vessel and brought the barge around to rescue him.

Direct causes

- Movement of the pontoon away from the submerged anchor point caused the float, anchor line and entangled mooring line to be pulled down, capsizing the dinghy.

Contributory causes

Safe systems of work

- There were deficiencies in the operation’s risk management process.

- The site-wide formal risk assessment did not identify and assess specific tasks performed by dinghies.

- There was no procedure in place for the task.

- The field-level risk assessment method was not appropriate for the multi-step task, and did not adequately identify the hazards and control measures (e.g. stowage of mooring line).

- Planning and supervision for the task was inadequate (e.g. handover process, vessel interaction, communication protocols).

Personal flotation devices

- The PFD, when fully submerged, did not inflate as designed.

- There was no formal process in place for inspecting and servicing PFDs, including pre-start checks.