Summary of incident

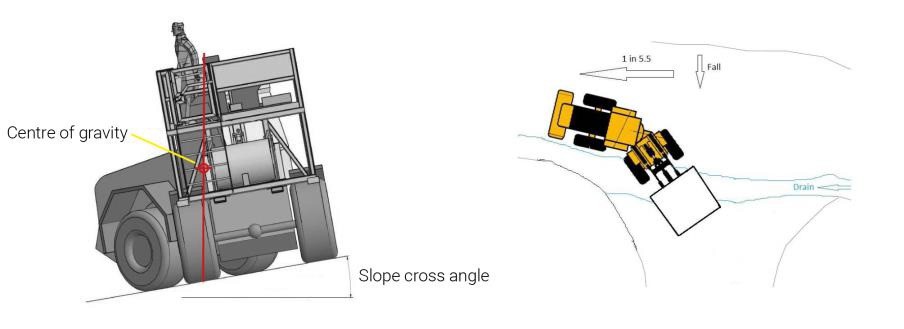

In February 2017, two underground workers were using an integrated tool carrier (IT) to complete a task at the intersection of a decline and a link drive. To access the work area the IT was parked in the decline with the front of the machine articulated (35°) around the corner of the intersection. The decline had a cross slope angle of 10.3°.

In order to undertake the task, the work platform, with a worker inside, was raised. When the basket reached a height of 2 m (and 30°off horizontal) the IT tipped onto its side. Fortunately, the worker in the basket and the IT operator were uninjured.

Note: The total estimated weight of the work platform was 3,106 kg and within the capacity for the IT.

Direct causes

- The IT was positioned and operated on a cross slope that exceeded the static stability threshold for the IT when articulated and with the work platform raised.

Note: The original equipment manufacturer’s (OEM’s) operating parameters and recommendations state that the IT’s static stability threshold maximum is 10° (applicable if IT is not articulated and the boom is fully lowered).

Contributory causes

- The operator was unaware of the static stability limitations of the IT and the effect of articulation and position of work platform on the stability of the machine.

- The inclinometer on the IT was not set up to measure the cross slope angle across the front axle.