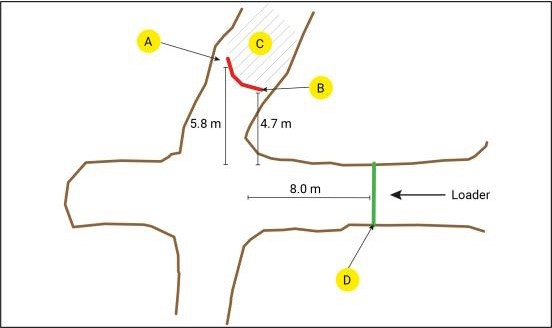

In February 2018 a loader operator was instructed to build a rock bund, using a loader, at the upper ledge of an open stope in an underground mine.

The operator trammed to the level, bogged dirt from a stockpile and then drove towards the open stope. On approaching the stope, there was a sign hanging on a chain that restricted unauthorised access to the stope and surrounding area. The operator removed the sign and conducted a visual inspection of the work area before returning to the loader and driving in close proximity to the edge of the stope to place the bund.

As the operator was tipping the load, the right hand side of the loader slumped and the operator exited the loader via the cab door. The loader kept moving forward under its own power and fell over the crest into the stope, coming to rest on the rill of ore below. The operator was uninjured.

Direct causes

- Lack of adequate controls to manage the risks for mining activities near a void.

Contributory causes

- No visual markers on the wall for the operator to position the bund safely.

- Reduced operator visibility:

- the edge to an open stope was located on a bend

- the loader was still articulated at the point of tipping (poor operator visibility)

- there was limited lighting.

- The operator misjudged the location of the edge leading into the void.